BIM2TWIN, the digital twin for the construction industry

Date:

Changed on 02/08/2022

It is a europeen project, of the RIA type (Research and Innovation Action), therefore it is not only a frontier research project. Indeed, there is an important part of innovation through the development of a common platform.

17 partners in Europe make up this consortium, including the CSTB at Sophia Antipolis (Centre Scientifique et Technique du Bâtiment), the project leader, Spada construction, Orange for France and others in Italy, Spain, Germany, Israel, etc., and two teams from Inria.

Many different construction processes and criteria need to be improved. Some criteria relate to quality, reliability, efficiency (performance), sustainable development (optimising resources, reducing the carbon footprint for example by factoring in transport), and others relate to safety.

Indeed, safety on a construction site is not just a question of rules. Beyond the usual performance indicators to measure the level of progress of a European country, the ultimate goal is zero accidents, which is still difficult to achieve. One might think that more rules, equipment and safety measures would suffice, but the reality is much more complex. The idea is to intensify prevention, notably by means of video surveillance (hence the involvement of the Stars team in this project). Real-time video analysis will make it possible to monitor human activities in interaction with machines, to issue safety alerts and to continuously ensure that safety equipment and procedures are respected.

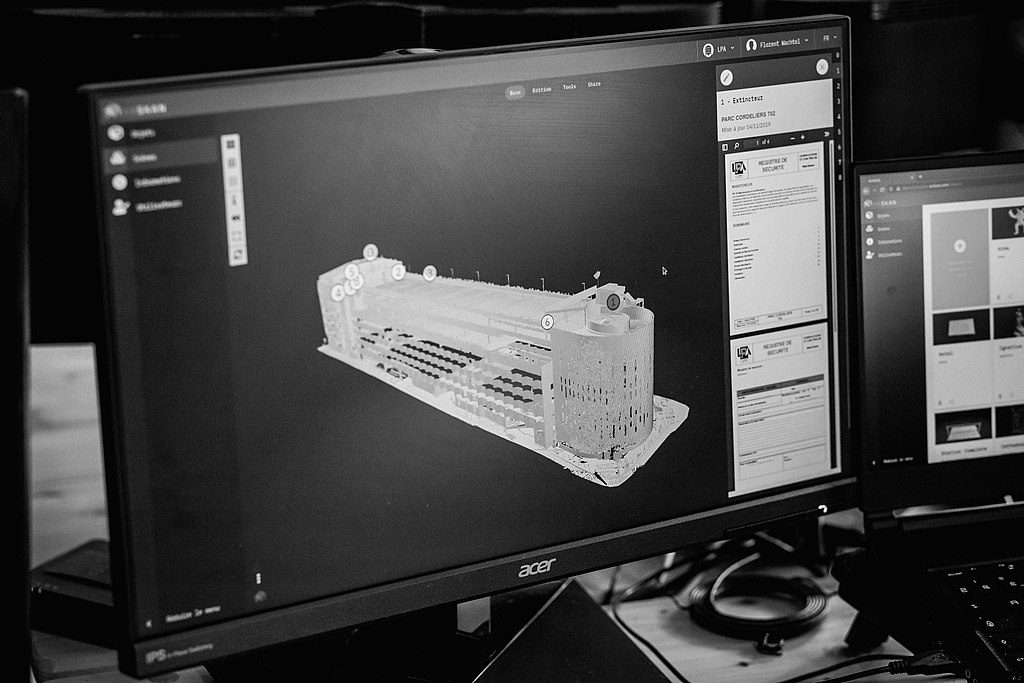

This digital twin platform is designed to continuously digitise the geometry and human activity on a construction site and to analyse the measurement data (e.g. 3D point clouds and videos).

The aim of the digital twin is to ensure that what is physically built conforms to the digital model created by an architect. The same applies to construction processes, including safety standards. The Titane team contributes to the processing, compression and analysis of 3D point clouds.

The monitoring of the progress of the building site and the quality control of the achievements are made possible by 3D reconstruction from measurements, semantic classification, shape analysis and metrology.

The Stars team is involved in real-time risk monitoring and detection of these risks with methods of continuous video analysis using automatic learning to understand the activity of workers on a site interacting with machines, issue alerts or detect risks. Continuous digitisation is also useful for prevention and legal archiving (documenting compliance with safety procedures such as the installation of guardrails).

The aim: to instrument a site, evaluate the number of cameras (or sensors) to be installed, the way to network them so that the platform can be rapidly deployed on a site (Orange). Sites serving as use cases will be made available to the teams for full-scale deployment, which explains the presence of construction companies among the partners (e.g. Spada construction in France).

The devices: laser sensors, cameras - including multispectral cameras (capable of seeing in the visible and infrared) - and mobile robots.

The publication of scientific articles in common with partners with whom we are not used to working will undoubtedly be a great opportunity to disseminate our work outside our niche community, especially towards the community of researchers contributing to industrial sustainability issues.

Ultimately, we would like to see the platform, the fruit of our research and the integration of technological components, used in production in Europe.

The same goes for the Stars team, which is using its technological platform to analyse human activities using videos.

The concept of digital twins is being developed.

The Titane team, for example, will participate in the digital road twin (with Cerema) for the predictive maintenance of pavements, bridges and engineering structures. Discussions are also currently underway on a project for the digital twinning of submarine construction sites.

Whether in the world of construction, factories, engineering structures or roads, manufacturers want to benefit from the revolution in artificial intelligence and systematic digitisation to increase efficiency.

Director of research - Project-team Titane

2004, route des Lucioles

BP93

,

06902 Sophia Antipolis