Some surgical operations require extreme precision, and their success depends largely on the experience and skill of the person performing them. This is the case with cochlear implants, which are prostheses used in cases of severe deafness. The cochlea is a small, spiral-shaped organ in the inner ear lined with cilia that transmit sound to the auditory nerve.

Cochlear implants stimulate the auditory nerve directly by electrical impulses. If everything goes as planned, patients who receive one of these implants can hope to recover a normal understanding of speech. However, during the operation, the implant must be pushed into the cochlea without being able to check whether everything is running smoothly, making it a very complex process with a risk of damaging the inner wall of the organ.

To standardise the procedure, assistance robots have been developed. While these have improved results, they do not prevent the implants from rubbing during insertion. “Numerical simulations of the operation carried out by our project team, Defrost, showed that one solution to this problem was to make the implant active, so that it can bend during insertion”, says Gang Zheng, head of the team at the University of Lille Inria Centre.

This observation led to the creation of the Robocop PRCE (Collaborative Research Project - Company), with the aim of developing a robotised cochlear implant. Led by Inria and financed by the French National Research Agency (ANR), the project involves the Laboratory of Physiochemistry of Polymers and Interfaces (LPPI), the Institute of Electronics, Microelectronics and Nanotechnology (IEMN), Inserm and Oticon Medical, a company specialised in auditory prostheses, recently acquired by world leader Cochlear.

Verbatim

This type of project is important for us in industry because it allows us to innovate with researchers who are experts in their fields.

Principal Research Engineer at Oticon Medical

Electro-stimulable polymers

To make the cochlear implant mobile, the researchers integrated an actuator, a component that allows the device to bend when stimulated by an electrical current. However, to achieve a working prototype, they had to overcome a number of scientific challenges concerning the choice of materials to use, how to ensure that the implant is slim enough and how to predict its behaviour and control it.

“We’ve been working on electro-stimulable polymers for the past 20 years or so and have mastered the manufacturing processes involved”, explains Cédric Plesse, University Professor and Deputy Director of LPPI. “Their sensitivity to low voltages makes them suited to this type of use”. Designed for robotics, these materials were made with no restrictions on their chemical composition, but an implant must be able to remain in the body for up to several decades without causing adverse effects. “We had to review each of the constituents to ensure that none would be toxic to the cells if damaged”, explains the researcher.

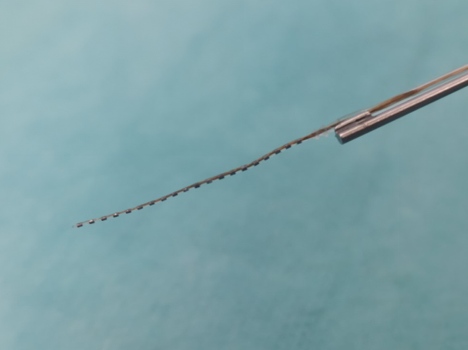

Another difficulty lies in the fact that the actuator must be sufficiently thin. In collaboration with teams led by Éric Cattan, University Professor and Researcher at IEMN, the chemists designed a component made up of two layers of polymers separated by an ionic liquid. The electrical engineers added connections to control the device and then integrated the actuator into the electrode array that makes up the implant.

“To reduce its thickness, we replaced the traditional electrodes – little metal rings - with micrometre-thin electrodes on the surface of the implant, which increase the contact surface with the wall of the cochlea”, says Éric Cattan. “With a total thickness of 20 micrometres, less than a hair, we made the implant much more flexible”. These design stages were carried out in consultation with Oticon Medical with the aim of ultimately manufacturing the new device on conventional production lines.

Modelling and simulation

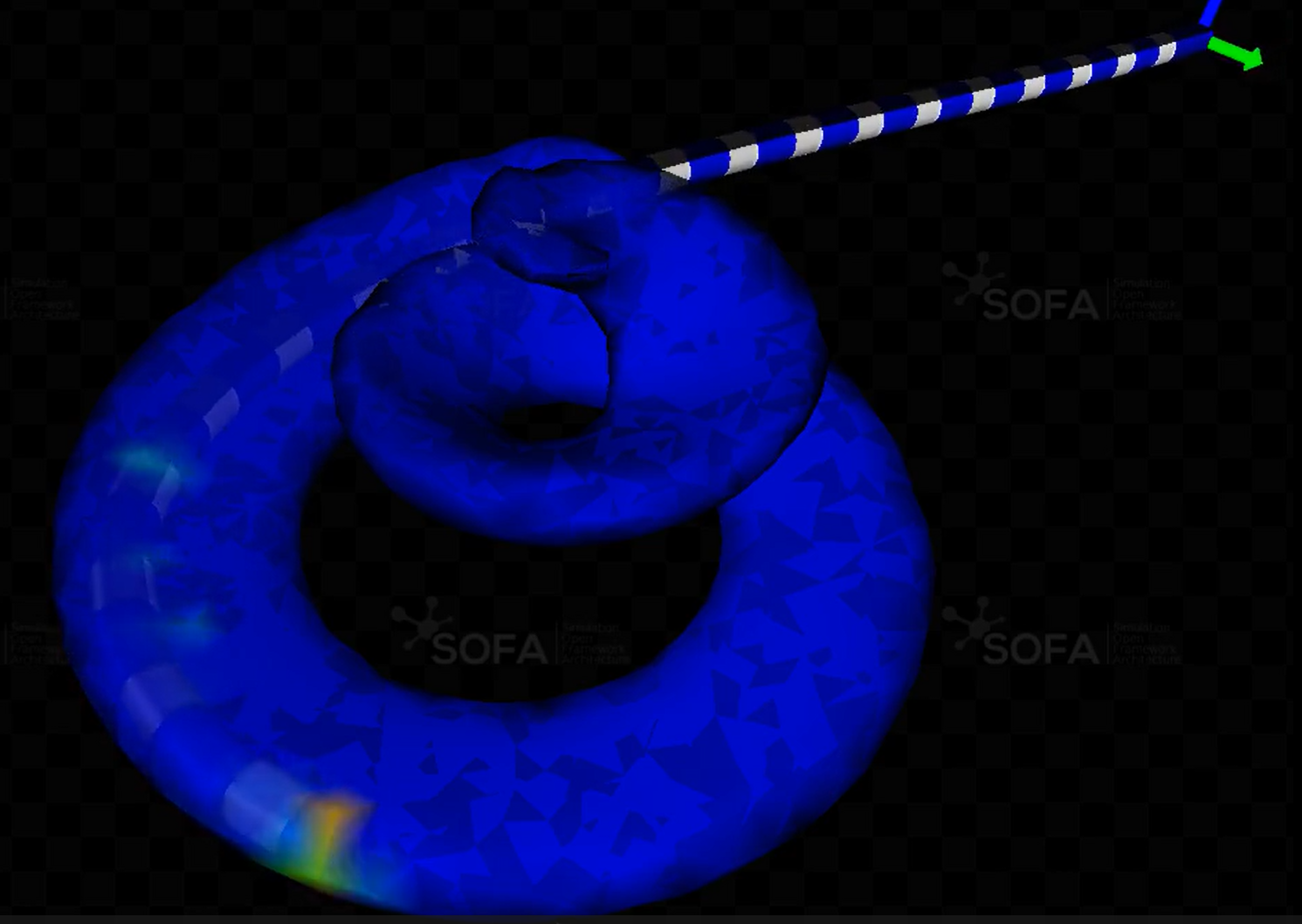

How do the teams predict how this new kind of implant will work? Modelling and simulation must be carried out even before new prototypes are produced. This is where the Defrost project team (a joint team between the CRIStAL laboratory and Centrale Lille), specialists in flexible robotics, comes in. “How will the device bend as a function of the electrical voltage applied? What effect will friction against the wall of the cochlea have on it?” asks Gang Zheng.

To answer these questions, the Inria scientists proceeded in stages. “We started by modelling passive implants, to which we added the actuator, before introducing the interactions with the cochlea”, explains the researcher. The team also innovated with the numerical method used: whereas their previous work was based on the finite element method, which required long series of calculations, they simplified the model using the Cosserat rod theory. Never before applied in this field, this approach involves describing movements in a different frame of reference.

“This model allows detailed analysis of the complex geometric relationships, forces and moments at the points of contact”, explains Lingxiao Xun, whose PhD at Defrost focuses on the subject. By reducing the calculation time required without compromising accuracy, the team was able to simulate implant deformations in real time, whether caused by the actuator or by friction. In the future, this should give surgeons visual feedback on what they are doing through real-time estimations of the position of the implant in the cochlea during the operation.

Major advances

To reproduce real phenomena as accurately as possible, digital models require measurements. “Before modelling, we sent all the known parameters of the materials used to Defrost”, says Cédric Plesse from LPPI. For some of the variables, however, the scientists had to use tests carried out with the first prototypes. “Yann Nguyen, a surgeon and university professor and researcher at Inserm, performed several implant insertions using a robot in a reproduction cochlea supplied by Oticon Medical”, says Gang Zheng. “By adding a force sensor to the system, we were able to collect data to feed back into our model”.

Next comes the development of the robot and implant control system. The force sensor measures the level of friction against the wall of the cochlea: if it is too high, the robot corrects the angle of insertion to reduce resistance, and therefore the risk of damaging the organ. Then, when the trajectory simulation indicates that the implant has reached the curvature of the cochlea, the system begins the bending process to complete the insertion. Several tests were carried out.

Verbatim

Our simulations successfully reproduced the real behaviour of the implant, and the surgeon completed several insertions.

Head of the Defrost project team

The project, which ends in September 2024, has led to major advances. The first clinical trials of an implant of this type will require several more years of development, but the scientists have already identified a number of avenues for perfecting the system. “Rather than gluing the actuator to the implant, as we have done here, we could root it directly in the electrode array”, explains Éric Cattan. “We have successfully developed stable polymers for this purpose, which facilitate biocompatibility”, adds Cédric Plesse.

Improvements must also be made to the modelling process, for example by taking account of nearby organs, such as the facial nerve. “We could also improve the precision of the operation by taking account of the unique shape of the cochlea in each patient”, says Gang Zheng. “For this, we’ll need to integrate individual 3D measurements obtained by tomography into the model”. This work will be carried out as part of a new project, ACCESS, funded by ANR and led by IEMN.

Besides cochlear implants, these results could be transposed to other areas in the future, such as neurosurgery or the insertion of catheters into a vein. The end of Robocop marks the beginning of a new chapter in surgical robotics!

Find out more

- « Hearing disorders, deafness: how to preserve and restore our hearing (in French), Inserm, 07/11/2023.

- « Rehabilitating hearing with a cochlear implant » (in French), Le Monde, 05/02/2024.

- « SOFA: a consortium on the theme of real-time simulation », Inria, 05/01/2016.

- « Adapting algorithms to people with auditory neuropathy » (in French), Inria, 23/11/2023.